AQL (最大可接受质量限值):

在进行抽样检查时,启迈QIMA 检验员遵循 ISO 2859 标准及其提供的表格。该文件由国际标准化组织 (ISO) 发布,是一项国际标准,在所有国家的法规(ANSI/ASQC Z1.4、NF06-022、BS 6001、DIN 40080)中都有相应的规定。

AQL (最大可接受质量限值) 抽样是一种广泛用于确定生产订单样品的方法,以确定整个产品订单是否符合客户的规格要求。根据抽样数据,AQL 标准可以帮助客户做出接受或拒绝该批次产品的明智决定。

检验报告将清楚地说明您的产品是否通过所选的可接受质量公差水平。

如何确定正确的样本大小和接受数量?

我们的专家将为您提供指导,确保您选择的检验级别和 AQL 值最符合您的需求。

使用我们的抽样计算工具测试您的产品检验 AQL。下面是我们设计的一个场景,帮助您了解它是如何工作的。

您要对 4000 个口罩进行检验,客户选择了普通检验 - 等级 II 和 AQL 2.5。请在下面的计算器中输入字段。

数量4000

检验级别:普通检验 II

AQL: 2.5

AQL 采样模拟器

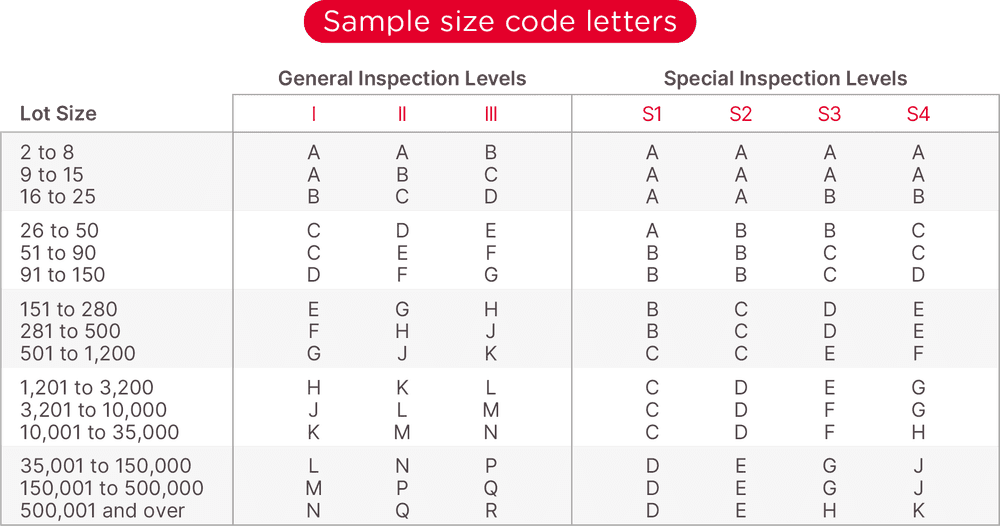

表 A

查找相应的批量大小(数量)和普通检验级别:代码字母 L 注:以下 AQL 表以 ANSI/ASQ 标准 Zq.4 - 2008 为基础

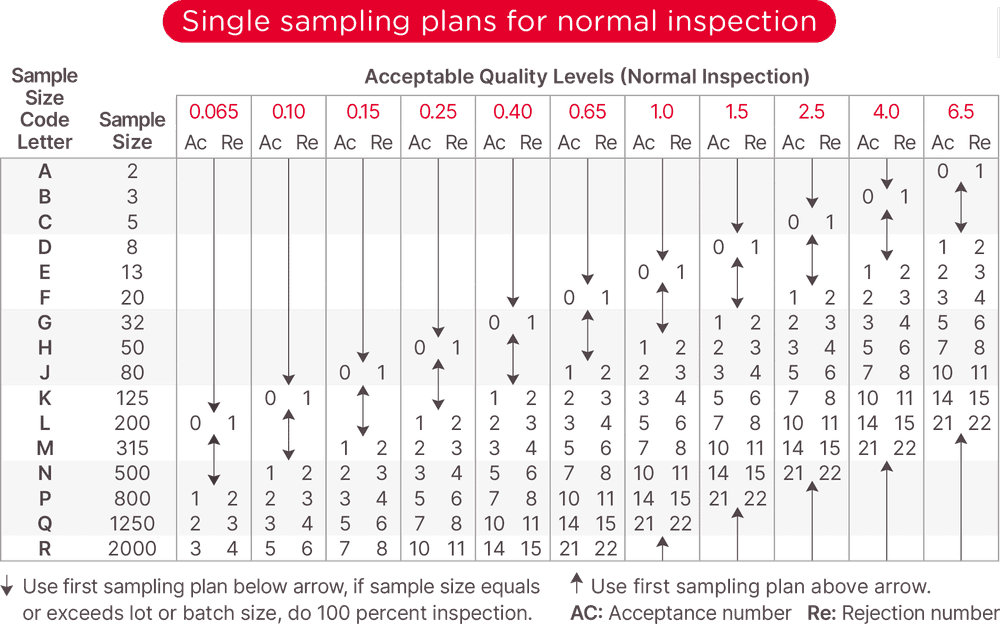

表 B

找到第 L 行(这是所需的 200 个样本量) 遵循 AQL 2.5,该样本量中不合格的单位不得超过 10 个。

现在,您可以继续模拟下一次抽样检验:

输入您的装运批次数量

选择普通/特殊检验级别

为所有缺陷(关键、主要、次要)选择 AQL

请参阅下表 A 和 B,了解对检验数量和接受缺陷的影响